AcousticsCQuietH | CQuiet 5 Point Hydraulic Elevator System Noise Treatment

C.E. Electronics – Acoustics Group is the only company dedicated to sound control solutions for elevator equipment and their operating environments. Our foundation in architectural acoustics and industrial noise control; coupled with our knowledge base of the elevator industries’ equipment, codes, and standards, provides you with the most qualified source to discuss and resolve your elevator equipment noise complaints.

CQuiet Sound Control Products provide effective noise control solutions regardless of hydraulic elevator system type: dry, submersible, or MRL. Hydraulic elevator systems generate both airborne and structure-borne sound migration and an effective sound control treatment begins with a thorough understanding of the different equipment types and building design variables that impact the sound levels and its migration.

Building design and construction can greatly impact equipment noise complaints, sound migration, widening areas of disturbance, and sound control treatment points. Drywall and masonry machine room construction require different treatment details. Elevated floor machine rooms, long hydraulic pipe runs, MRL systems, or other unique features require a different focus of sound control treatment compared to a basic ground-level machine room directly adjacent to the hoistway.

Equipment operational sounds are carried through the oil and steel piping into the cylinder, then into the car frame and ultimately through the guides to the rails and on into the building structure. Mufflers or silencers will reduce the pulsating sounds and acoustic energy traveling through the oil; however, they offer no reduction in the sound traveling through the steel pipe itself. Airborne sound radiates from the pipe and structure-borne sound into the building structure from migrating through standard pipe supports, installing an isolation coupling will help reduce sound migration from the pipe.

Elevator modernizations from a dry to a submersible type system frequently lead to noise complaints of the new system being louder. Airborne sound levels are increased as the entire tank of the submersible system becomes a sound source as the contained sounds are radiated from the sides. Our experience has shown that the actual sound levels do not vary greatly; however, the differences in their generated frequencies creates a perception of being louder as this frequency has shifted into the sweet spot of human hearing as well as their interaction with the building elements.

C.E. Electronics – Acoustics Group will provide you the support needed and our CQuiet Noise Control Product line has the solutions to address your most difficult hydraulic elevator installations.

Product Profile

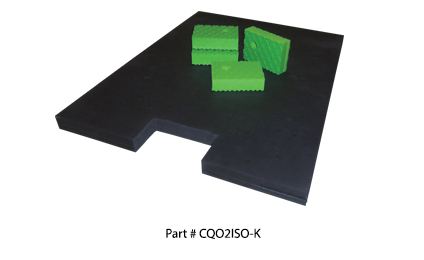

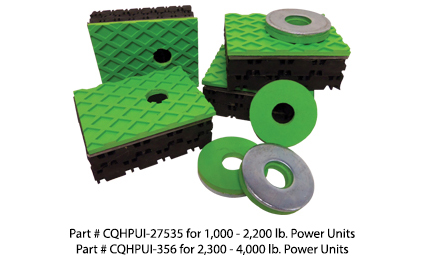

Our new CQuiet Hydraulic Power Unit Isolation series provides an effective engineered solution for all hydraulic elevator system types. The CQHPUI series provides high vibration isolation for all hydraulic power units with a leg base design and the CQO2ISOK offers the best solution for OEM power units where the motor/pump assembly is mounted on the floor-supported tank bottom plate.

The CHPUI series incorporates multi-density pads and a steel plate for uniform distribution of the load over the entire pad surface area. The mounting thru-hole in the steel plate is oversized from the pad holes preventing metal-to-metal contact of with the anchor bolts.

CQO2ISO-K is also a multi-density five-pad isolation design, four corner pads with a pad providing isolation and proper support for the location of the motor/pump assembly, preventing possible distortion of the tank’s bottom plate due to the high motor torque.

CQuiet Hydraulic Power Unit Isolation kits include isolated washer assemblies, preventing a mechanical short-circuit through standard washers and the anchor bolts.